High-Performance Materials and Coatings for Industry

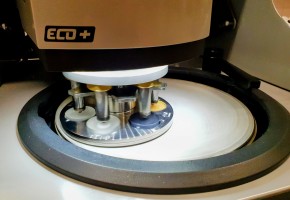

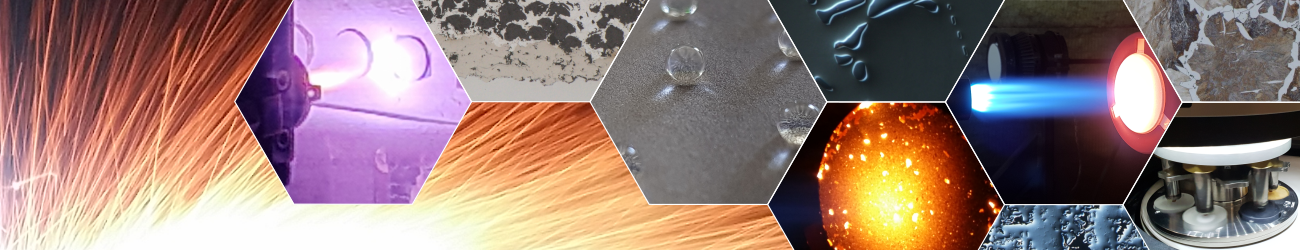

High-Performance Materials and Coatings for Industry research group focuses on processing, research and development of high-performance coatings for aerospace, automotive, power energetics and biological/biomedical applications. As an example, the high-temperature coatings, cavitation-resistant coatings and wear-resistant coatings produced by means of thermal spraying or electrochemical methods can be mentioned. The members of the research group coming from materials science and engineering, physics, chemistry and computational science branches also focus on research, development and failure analyses of bulk metallic alloys, surface and interface interactions, and powder processing in close collaboration with Industry. The research group is as well responsible for the development of uncommon and unconventional testing techniques like cavitation resistance testing apparatus, cyclic furnace oxidation test, burner-rig test, etc.

Results

19.05.2025

Failure analysis of copper heating blocks designed for brazing…

Two types of copper heating blocks, namely Cu-HCP and CuCr1Zr, with an electroless nickel-phosphorous (NiP) bond coat and a chromium-nitride (CrN) top coat produced by physical vapour deposition (PVD…

Read more »

17.04.2025

Bone Response to Biodegradable Metals and In Vitro Evaluation of…

This review focuses on the bone response to biodegradable metals used in temporary osteosynthesis devices. These implants are designed to degrade in vivo, fully dissolving after stabilizing fractures…

Read more »

23.10.2024

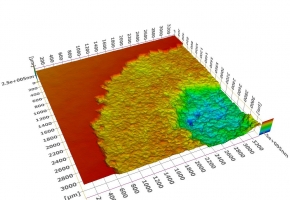

A Comparative Study of the Impact of La2O3 and La2Zr2O7…

We report, for the first time, the effect of lanthanum zirconate (La2Zr2O7) particles on the microstructure and mechanical behavior of an experimental molybdenum oxide dispersion-strengthened alloy.…

Read more »

19.10.2024

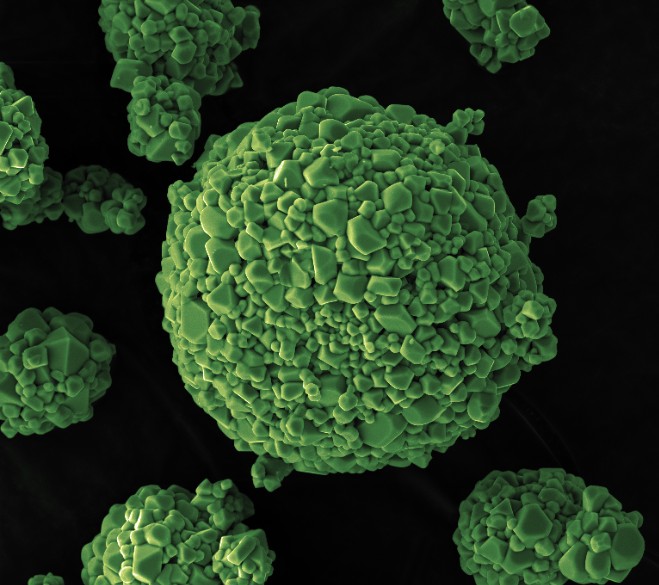

Porous titanium/hydroxyapatite interpenetrating phase composites…

This study introduces the first fabrication of porous titanium/hydroxyapatite interpenetrating phase composites achieved through an innovative processing method.

Read more »