Laboratory of Materials Analysis

The Metallographic Laboratory is a high-tech laboratory for the preparation and evaluation of metallographic samples. At the same time, it is the application laboratory of Metalco - ATM Qness GmbH, a major European manufacturer of metallography devices and hardness testers.

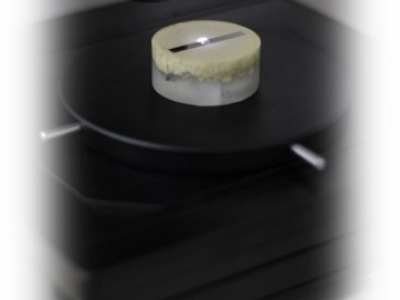

The Laboratory is equipped with up-to-date equipment, including the latest high-precision cut-off machines (Qcut 200A, Qcut 350A), equipment for the complete preparation of metallographic samples (Qpress 50, Qmount, Qpol 300 A1+) and hardness and microhardness testers for Vickers, Brinell and Rockwell hardness testing (Qness 60 A+, Qness 750).

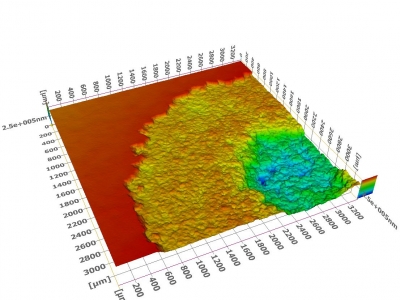

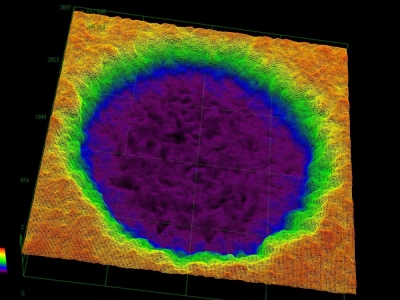

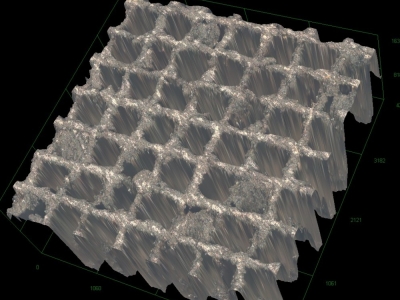

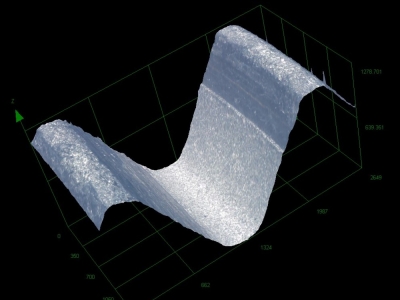

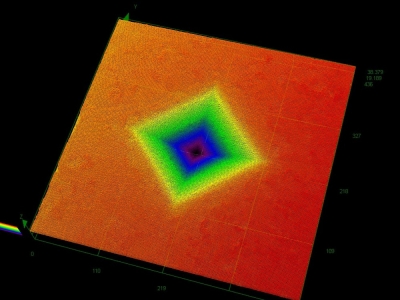

The Laboratory also has analytical scanning electron microscopes, X-ray diffractometers and state-of-the-art digital microscopes from Olympus, DSX510, DSX110 and LEXT OLS5100 with high resolution, 3D imaging and measuring of the samples observed, including complete image processing and roughness measurement.

COOPERATION WITH INDUSTRIES

The expert research team is highly qualified to perform material analyses and their evaluation using the latest methods and techniques. The Laboratory is an excellent research facility with long experience in finding solutions to production problems in industries in the field of materials engineering.

AMONG OTHER THINGS THE LABORATORY CAN OFFER

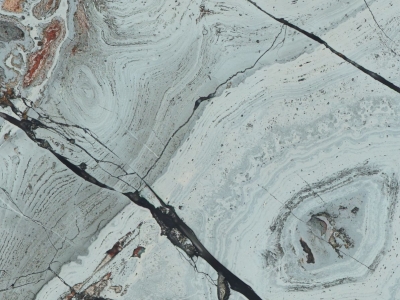

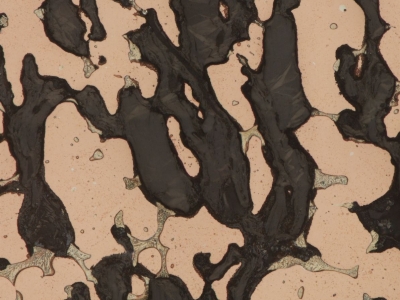

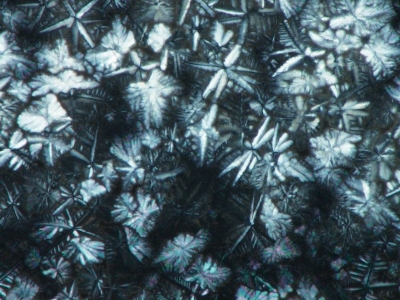

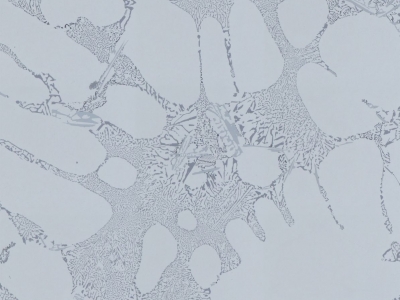

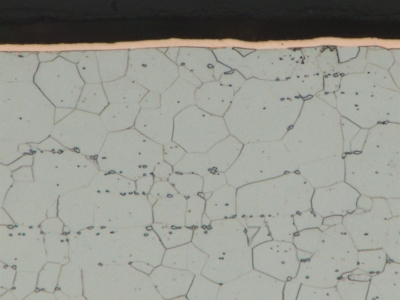

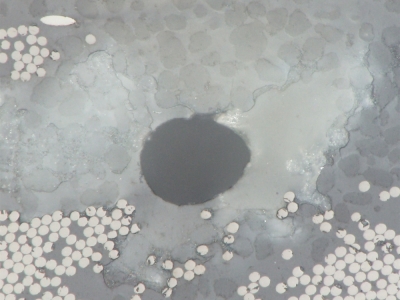

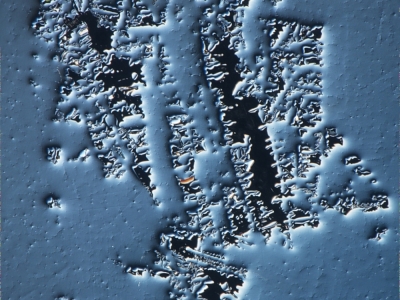

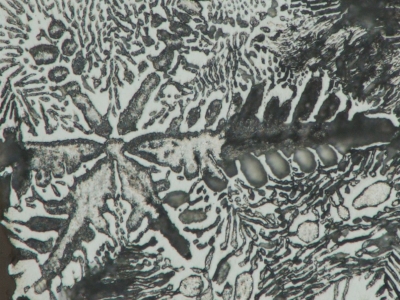

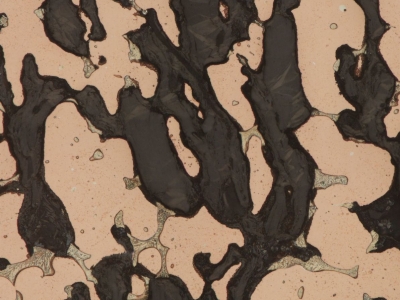

- Structural analysis of metallic and nonmetallic materials (macro microstructure, inclusion content, grain size, DAS, porosity, analysis of graphitic particles, etc.) according to valid standards.

- Testing of mechanical properties (hardness and microhardness Vickers, Knoop, Brinell, Rockwell testing, tensile tests, etc.).

- Analysis of chemical composition (Optical Emission Spectroscopy with Spark Excitation‚ analysis of solutions by lnductively Coupled Plasma Optical Emission Spectroscopy, EDS microanalysis).

- Testing of the quality of initial metallurgical material.

- Control of possible confusion of structural materials, including determination of chemical composition.

- Analysis of material properties after technological processes (heat treatment, forming, etc.).

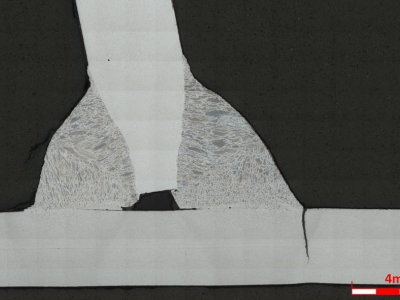

- Control of the quality of welded joints.

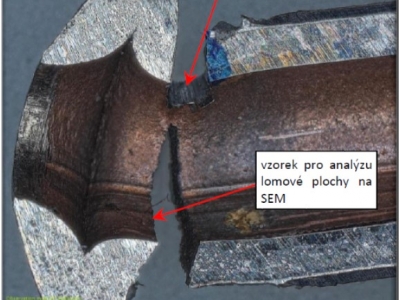

- Analysis of the cause of the fracture of material during processing.

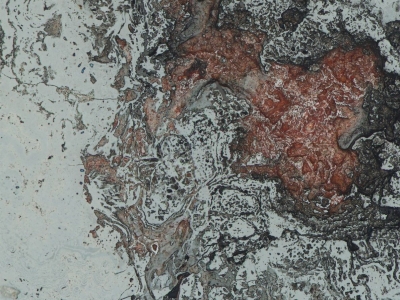

- Analysis of the cause of the components fracture during operation (wear).

- Complex analysis of layers and coatings (coatings prepared via thermal spraying, galvanic coatings).

- Development and optimization of metallographic preparation techniques for specific materials for industrial laboratories.

The price for analyses is determined individually based on the request.

Do not hesitate to contact us at metlab@vut.cz

METALLOGRAPHIC WORKSHOPS AND TRAINING ACTIVITIES

One of the further specializations of the Laboratory is the holding of traditional metallographic workshops, which are specialized in further education of the professional industrial community.

The workshops are focused on topics and problems that are most required by industrial partners, e.g.:

- preparation of metallographic samples from various materials, including evaluation,

- control of heat treatment of metallic materials,

- quality control of welded joints,

- metallographic analysis and measurement methods for films and coatings,

- organization of thematic workshops focused on further areas in the field of materials engineering, according to customer requirements.

Head of Laboratory: Martin Juliš, Ph.D.